Processes

Introduced on this page are some of the main synthesis processes that are able to be performed by a CGP, these processes are patented and possible with Innovative Potential™. Due to the nature of processes themselves, each process is displayed as a general manufacturing example, but all are dependent on a patented CGP.

Electrosynthesis

You can use a CGP electrochemical system to activate molecules into synthetic intermediary powerhouses.

The benefit of using a CGP-activated intermediary in your organic syntheses is the removal of the need of a catalyst, which are typically heavy metals with a high environmental impact and legacy.

Green your chemistry with a CGP-activated molecule today!

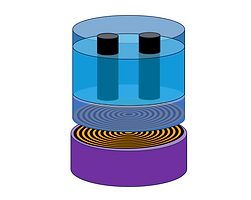

Polymerization

With the correct anode material a CGP can act as a producer of unpaired electrons (radicals) for your polymerization reactions.

A flow through CGP model can act like a spider's spinneret, allowing you to separate the polymer strand from the recirculating monomer suspension, saving you separation time and synthesis resources.

Precipitation

Some processes in food manufacturing are pH-dependent, such as curdling.

By using a divided flow-through CGP design, pH-dependent precipitation reactions can be controlled for more efficient production systems.

Imagine being able to generate your own coagulating agent in situ just by using a CGP.

Chlorination

A CGP can also act as a chlorination device providing chemically reactive molecules, or for producing potable drinking water from environmental sources.

Remediation

Do you have a regulated molecule in your waste streams?

Control and reduce your waste stream effluents with CGP remediation!

Flow-through and batch circulation options available.

Induction

When a CGP can function through wireless induction, why get your hands dirty, or your instruments?